Driving better environmental performance

- Home

- > Fit for the Future – our commitment to sustainability

- > Driving better environmental performance

A key pillar of our sustainability strategy focuses on reducing the direct and indirect environmental impacts of our products and on helping to drive the decarbonisation of heating. We recognise the urgent need to reduce global emissions and manage resources efficiently, and our actions will ensure we play our part in meeting these global aims.

Our existing products can operate effectively with all heat sources, but as alternatives to fossil fuels are developed, we will continue to innovate and introduce complementary products as part of a coherent offering for lower and zero carbon heating systems.

In the design, manufacture and distribution of our products, we are working to understand our environmental impacts and will target improvements as part of a long-term journey to net zero emissions. We will engage our value chain in this work, looking to optimise our packaging design and reduce the environmental impact of the raw materials that we use in our products. We also have a clear role to play in influencing positive behavioural change for consumers to encourage the decarbonisation of heating.

KEY METRICS

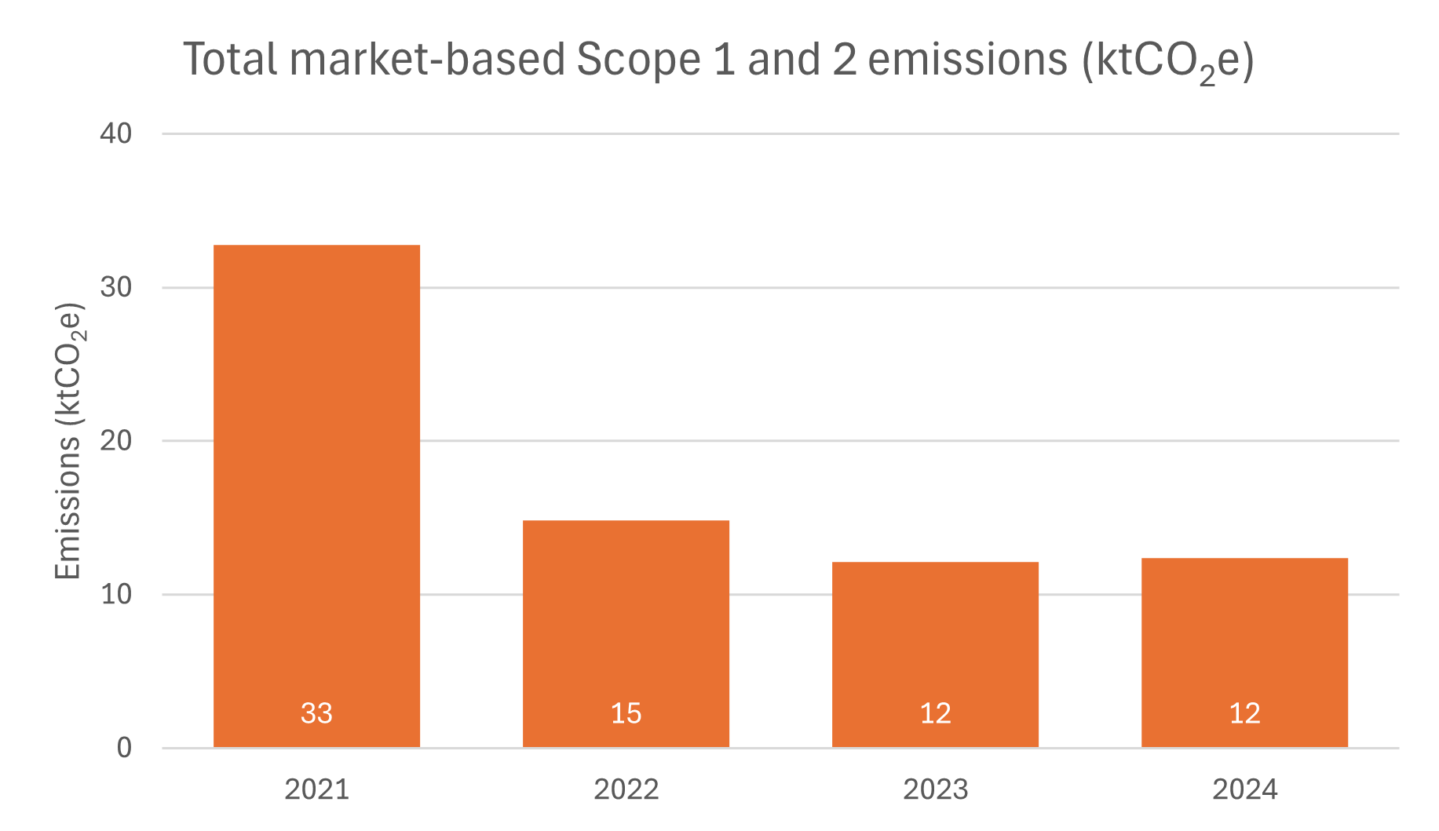

| Total market-based Scope 1 and 2 emissions (tCO2e) | ||

| Baseline | 2023 | 2024 |

| 32,757 | 12,122 | 12,382 |

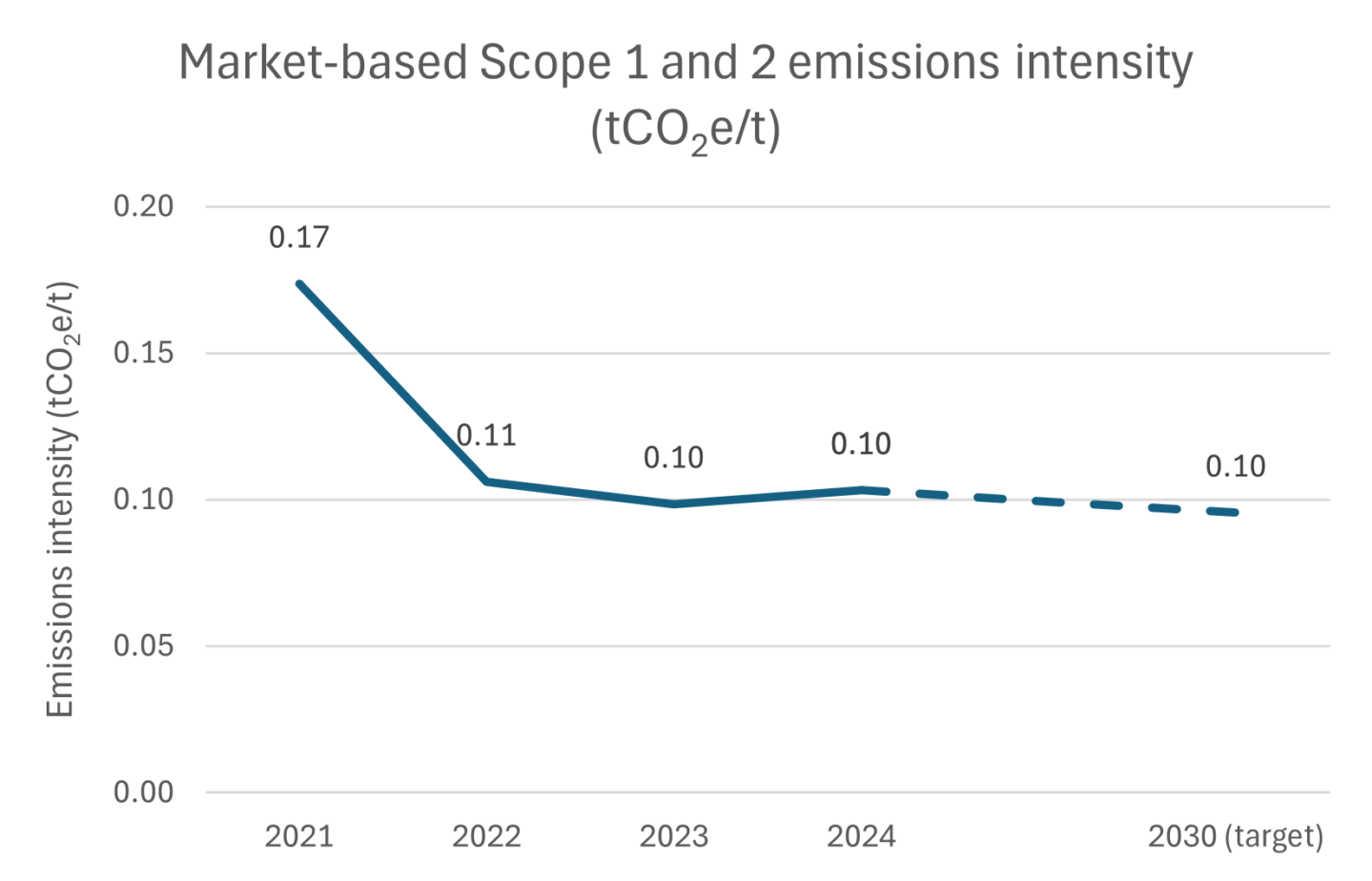

| Total market-based Scope 1 and 2 emissions intensity (tCO2e/t) | ||

| Baseline | 2023 | 2024 |

| 0.17 | 0.10 | 0.10 |

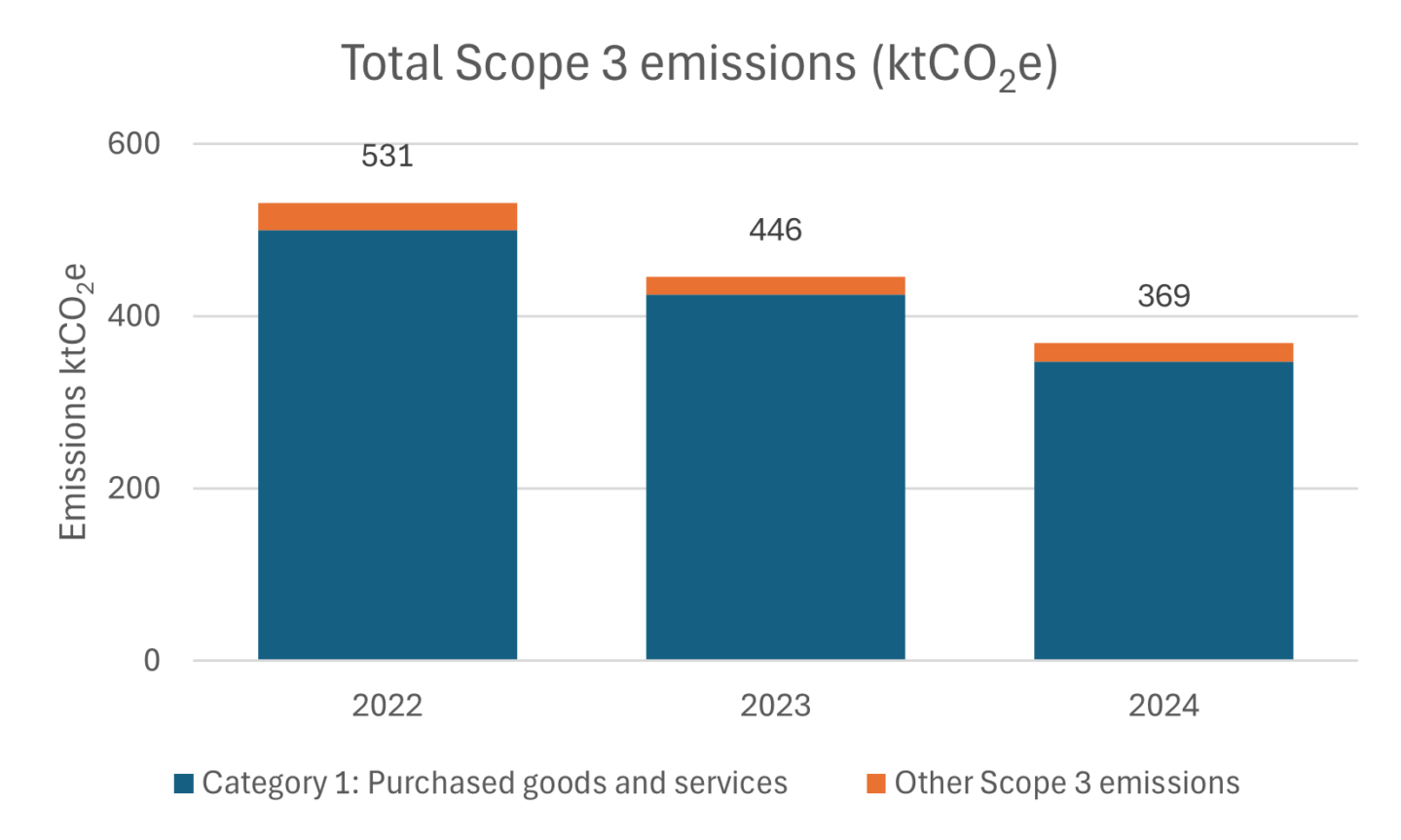

| Total Scope 3 emissions (tCO2e) | ||

| 2022 | 2023 | 2024 |

| 531,456 | 445,516 | 368,654 |

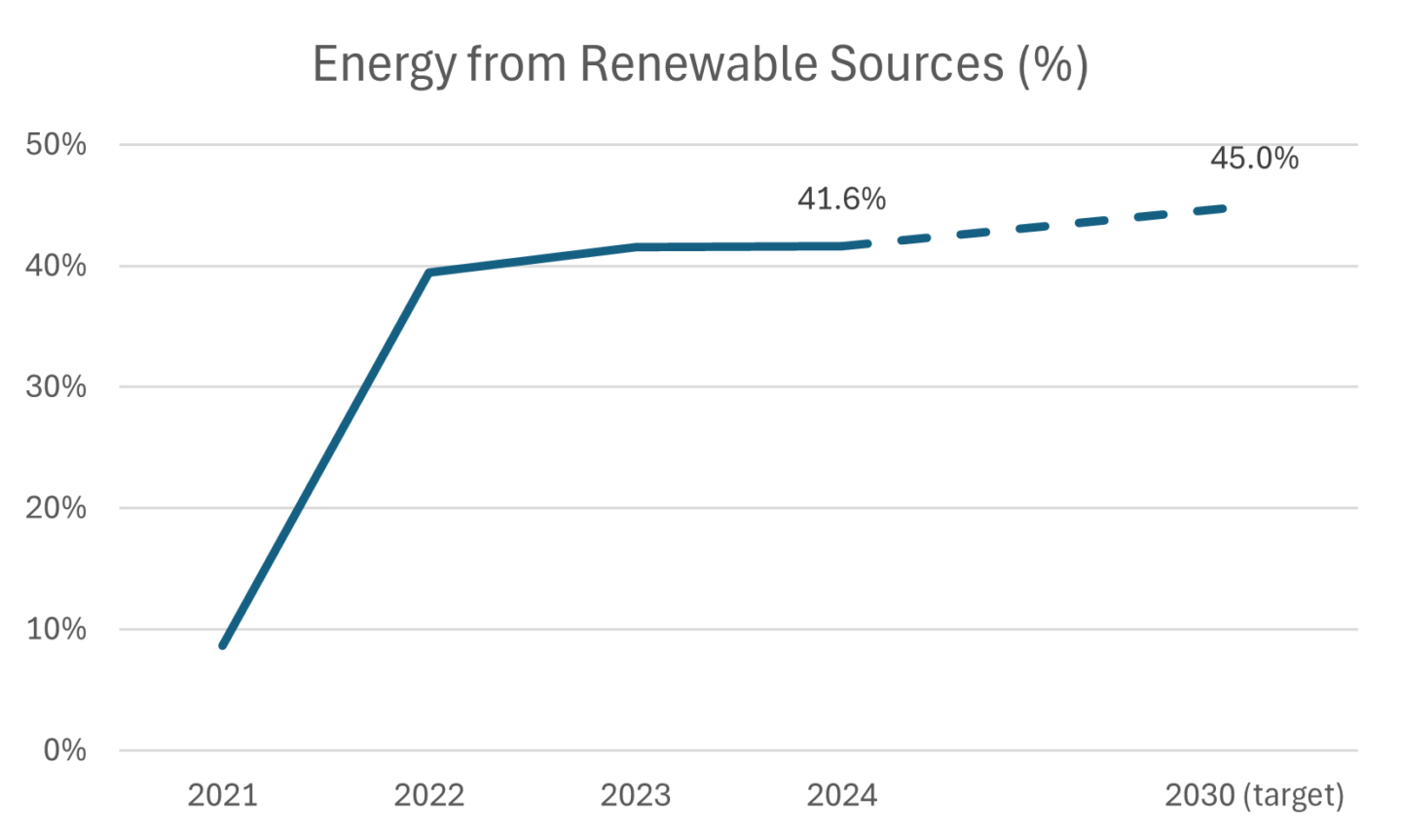

| Energy from renewable sources (%) | ||

| 2022 | 2023 | 2024 |

| 39.5% | 41.5% | 41.6% |

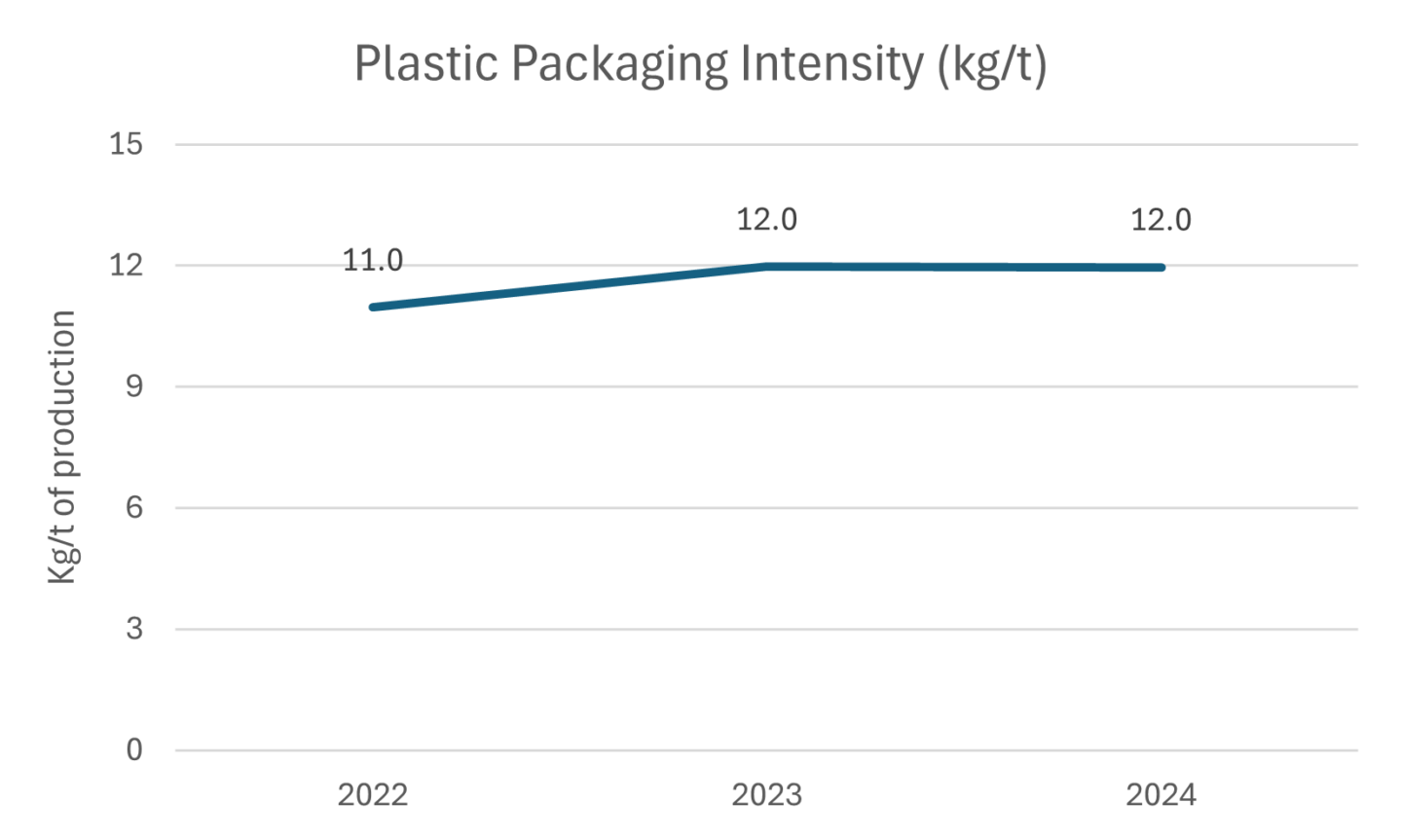

| Plastic packaging intensity (kg/t) | ||

| 2022 | 2023 | 2024 |

| 11.0 | 12.0 | 12.0 |

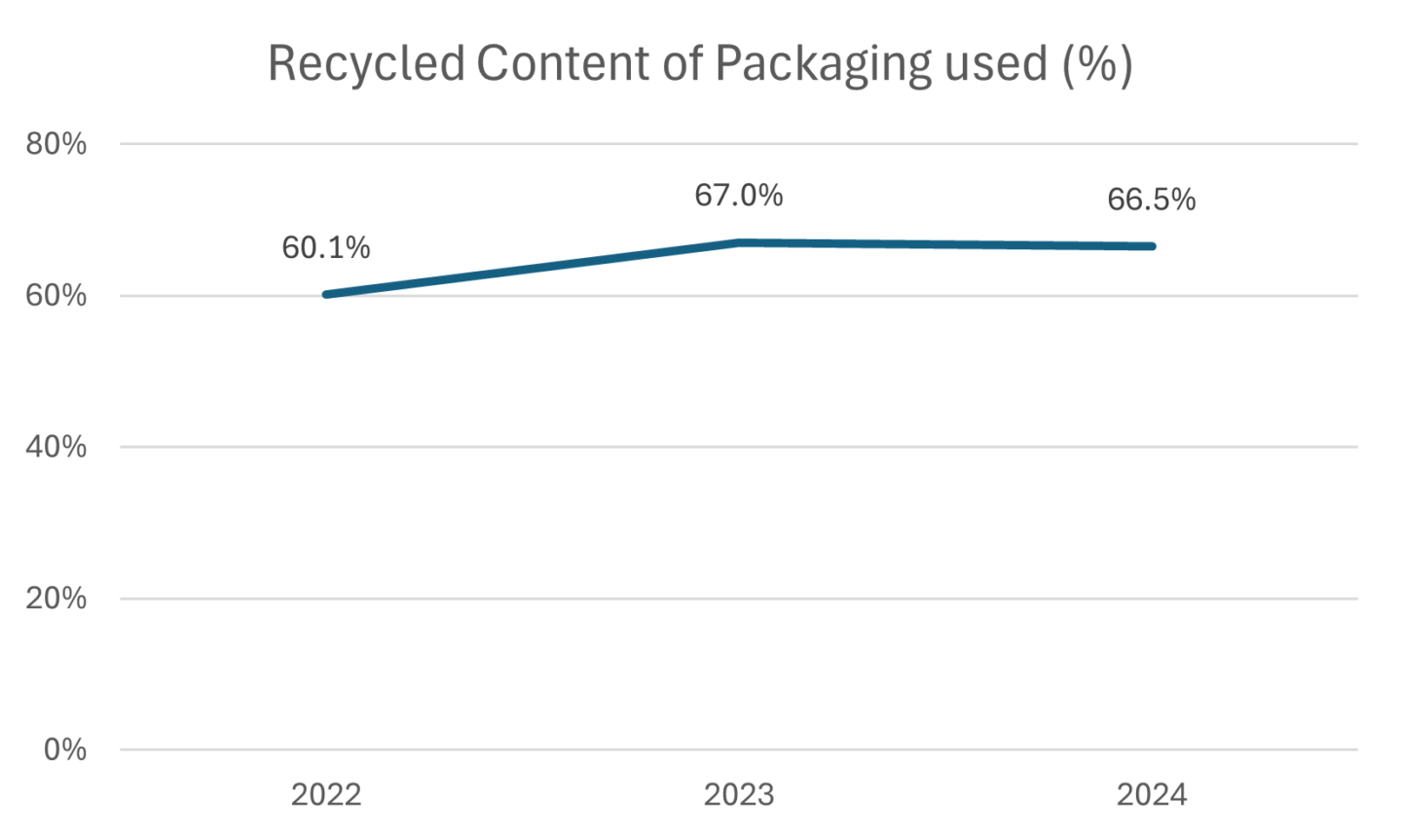

| Recycled content of packaging material used (%) | ||

| 2022 | 2023 | 2024 |

| 60.1% | 67.0% | 66.5% |

-

In 2024 our absolute Scope 1 and 2 carbon emissions, measured in tonnes of carbon dioxide equivalent, were 62.2% lower than the baseline in 2021. The main improvement was achieved through an increased use of renewable energy. A market-driven production volume reduction also contributed to reduced emissions, as did measures to improve energy efficiency.

-

Our emissions intensity, measured in tonnes of carbon dioxide equivalent per tonne of product produced, was 40.6% lower in 2024 than in the baseline year of 2021. Similar to our absolute emissions, reductions have been driven primarily by an increased use of renewable energy.

Despite an increase in 2024, this shows significant progress against our target to reduce emissions intensity by 45% by 2030.

-

Scope 3 emissions reduced by 17.3% in 2024 and are now 30.6% lower than in 2022. This reduction has been driven by reductions in purchased goods, related to improvements in data and a market-driven production volume reduction. Note that we exclude emissions from category 11: Use of Sold Products from this analysis.

-

In 2024, the percentage of energy from renewable sources continued to increase despite a lower proportion of energy produced by onsite solar generation. This increase was influenced by using a greater share of our energy in Turkey, where renewable energy usage is higher than the average across the Group.

We continue to make progress towards our target of 45%.

-

Our plastic packaging intensity – the weight of plastic packaging used per tonne of finished product produced was down 0.1% in 2024. Reductions in Turkey were offset by expansions in the coverage of our data to additional products. Our efforts to reduce the amount of packaging, especially plastic, that we use, continue.

-

The recycled content of our packaging decreased in 2024. This was mainly driven by an expansion in the scope of data collection to include previously excluded products and routes to market. Our efforts to reduce plastic packaging should also increase the recycled content as the cardboard we use across the Group contains 97.9% recycled content on average.

Please find a selection of our performance reports below: